Solar Drying

Solar sludge drying is an ideal method of reducing sludge volumes and disposal costs, particularly in the Australian climate.

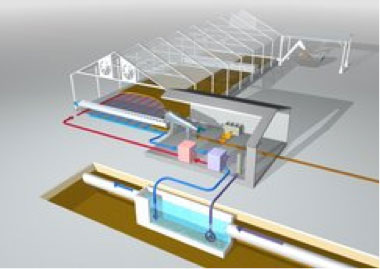

The HUBER SRT system is a unique and highly efficient process whereby sludge is dried in a greenhouse using incident solar radiation and artificially generated wind to evaporate water from the sludge.

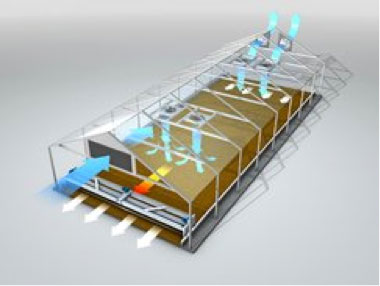

A special sludge turning system performs spreading, granulation, turning, mixing and back-mixing of sludge as well as its transport from one end of the greenhouse to the other.

The produced free flowing granulate is easy to handle due to its high solids concentration generally containing 70-90% dry solids.

Find out more

The sludge turner is the core of the drying system and consists of a rotating double shovel mounted on a travelling frame. The double shovel fulfils two functions:

1. Sludge turning deviceSludge turning: As the sludge turner travels forwards with the rotating double shovel, the sludge is mixed, broken up, aerated and transported. The sludge is completely restacked as the sludge turner travels from one end to the other. Each individual sludge grain inside the greenhouse is moved within a short period of time. This is ideal for a good drying result and prevents odours.

2. Sludge transport:

2. Sludge transport:

The sludge turner takes up some sludge at a defined point and transports it inside its shovel to another point. This permits back mixing of dry sludge into wet sludge. Sludge feeding and removal can take place at opposite ends or the same end, as requested.

Maximum flexibility of sludge feeding and removal gives freedom of design. It is for example possible to build the greenhouse up to the boundaries of the WWTP grounds and save space for roads or turning curves.

The sludge turner is made of corrosion resistant stainless steel and travels on low driveway walls to avoid shadows. The machine pulls itself through the greenhouse along chains and is safely guided.

- Climate probes, ventilators and ventilation flaps are installed in the drying plant to ensure ventilation at the right time and to generate sufficient airflow on the sludge surface. Ventilation is regulated on the basis of continuously measured water absorption capacity of outside and inside air; excessive water condensation is prevented. Ventilators blow dry air over the bed of freshly turned sludge. The climate control system uses not only theoretical calculations, but also empirical operation and measurement data.Seasonal climate and external heat sourcesDrying efficiency depends directly on the climatic conditions with less water being evaporated in winter than in summer. Different strategies can be applied to process continuously generated sludge volumes:

- Operator accepts greatly varying product dryness and selects sludge disposal options accordingly.

- A sludge buffer tank is used for sludge storage in winter and emptied in summer when dryer performance is high.

- Solar drying is supported with external energy sources in winter.

- Several of these options are combined.

An eco-friendly method of supplying additional energy is the use of a heat pump, which lifts thermal energy, extracted through heat exchangers from the WWTP effluent, to a higher temperature so that it can be used for sludge drying. Other heat sources can also be used as available (e.g. exhaust heat).

Supply of additional heat through highly efficient floor heating ensures maximum heat transfer with minor losses. Efficient evaporation permits space saving system design.