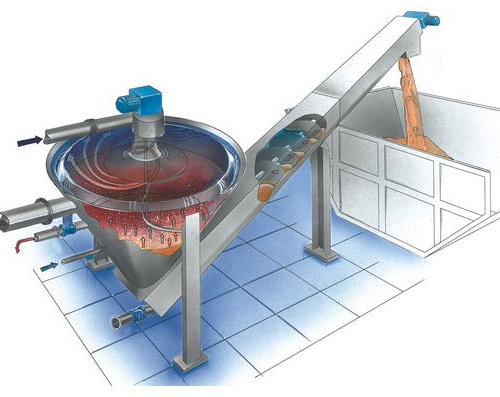

Advanced Grit Washing + Dewatering

The HUBER RoSF4 Grit Washing Plant is the highest performing grit washing and dewatering system in the world with over 1500 installations worldwide

The COANDA Grit Washing Plant combines grit classifying and grit washing in a single and compact unit. With installations in most Australian capital cities including Australia’s largest Grit Washing and Dewatering facility at Sydney Water’s Malabar STP, NSW, the RosF4 provides the highest quality of grit for disposal.

By using the COANDA effect the process of classifying can be combined with the process of sorting to ensure a continuously high separation efficiency and outstanding washing performance.

The optimal flow pattern in the COANDA Grit Washer leads to a > 95 % separation of 0.20 – 0.25 mm diameter grit particle.

The entire system is fabricated from stainless steel.

Find out more

- Highest performance on the market—90% dry solids and less than 3% residual grit

- Simple reliable operation

- The original fluid bed washing system, proven in over 1500 installations

- Full stainless steel construction

- Intermittent screw operation prolongs life

The performance of the RoSF4 relies on the geometry of the settlement trap, patented inlet distribution cone and fluidised bed washing zone. As flow enters the unit, the Coanda Tulip distributes the flow across the full surface area of the settlement tank. As particles settle, they are subject to a fluid bed generated by up-flow wash water, which rigorously washes the organic layer that coats the grit particles.

The organic rich wash water is discharge via an actuated valve, the supernatant overflows through the top circular weir. Washed particles settle to the bottom of the settlement trap, and are scraped the centre drop point to within the screw conveyor feed zone.

The screw is controlled intermittently via a hydrostatic pressure probe that monitors the grit mass within the classifier.