Step Screen

HUBER’s subsidiary in Sweden, Hydropress AB, invented Step Screen® in the early 1980’s Since then over 100 HUBER Step Screens have been installed in Australia and over 4000 units are operational worldwide.

The STEP SCREEN® System is widely accepted and successful due to its function and easy-to-follow operation principle.

The Step Screen has a very high separation efficiency due to the narrow slot width and the screenings carpet that is generated during operation. Slot widths are available in either 3mm or 6mm. The Step Screen design is self-cleaning due to moveable lamellae so there is no requirement for spray water or brushes.

Step Screen is easy to retrofit to existing channels with widths varying from 500mm to 2000mm. The discharge height from the base of the channel is flexible due the variable angle design and can be up to 3.5m. The step screen is capable of processing up to 3000L/s.

Find out more

Designs are available for high grit content, using a special flushed bottom step.

Intermittent operation increases plant reliability and reduces maintenance.

The motor linkage system has been developed from the well-proven and patented link system. To the benefit of our customers we intentionally avoided difficult-to-maintain chain drives. With the new linkage design we are able to master the bending moments on the blades, especially with high water levels.

Step Screen® consists of step shaped bars, with every second bar connected to the moveable carriage and whilst the others are fixed. The bar spacing is provided in either 3 or 6mm.

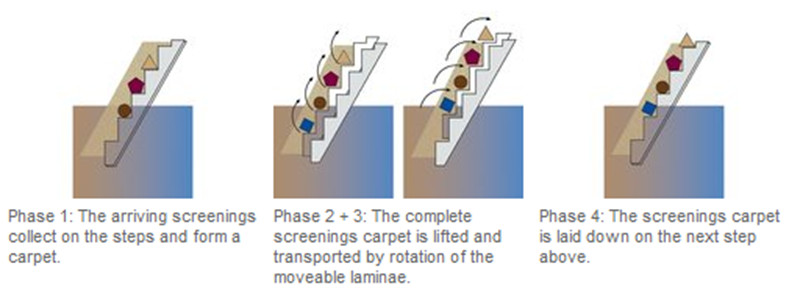

Screenings accumulate on the screen surface to form a screenings mat, which further aids separation. The stepping action is initiated via head loss control or upstream water level.

An eccentric stepping action generated by the head shaft and eccentric block moves the screenings mat up the screen face, and to the machine’s discharge point.

Energy is transferred from the head shaft along side plates that connect to the movable carriage. At the bottom the side plates are supported by a heavy duty link system. There are no submerged bearings.

- The are many benefits to the Step Screen

- Unrivalled for more than 20 years

- The original step screen design

- Screenings are lifted right from the bottom of the channel due to a special bottom step design

- High capacity as the flow passes the screen surface only once

- High separation efficiency due to the narrow slot width and the produced screenings carpet

- Gentle and complete screenings transport due to the counter-current principle

- Optimally adjustable to individual hydraulic conditions due to the variable installation angle

- Manufactured from stainless steel and acid treated in a pickling bath.

- Self-cleaning effect due to moveable lamellae (no spray water, no brushes)